Breaking the Heat Barrier with Diamond-Cooled Chips

In a revolutionary move, a US company is utilizing synthetic diamonds to significantly boost the performance of microprocessors, even as they generate massive heat. These diamonds serve as an efficient cooling mechanism, enabling one of Nvidia's strongest chips to run three times faster than before. The technology originates from Augsburg.

The reign of Moore's Law, which predicted a two-year doubling of computer chip computing power, has been disrupted as processors have reached their cooling limits. Both the main processor (CPU) and graphics processor (GPU) struggle to handle temperatures above 100 degrees in the long run. Addressing this issue, researchers have been searching for alternative architectures or more efficient cooling methods.

One exciting new development comes from a US company that uses diamonds for cooling, improving traditional chips' functionality. This innovative approach, led by the US firm Diamond Foundry, which acquired Audiatec last year, has yielded promising results in enhancing chip performance and longevity.

The Swabian Connection

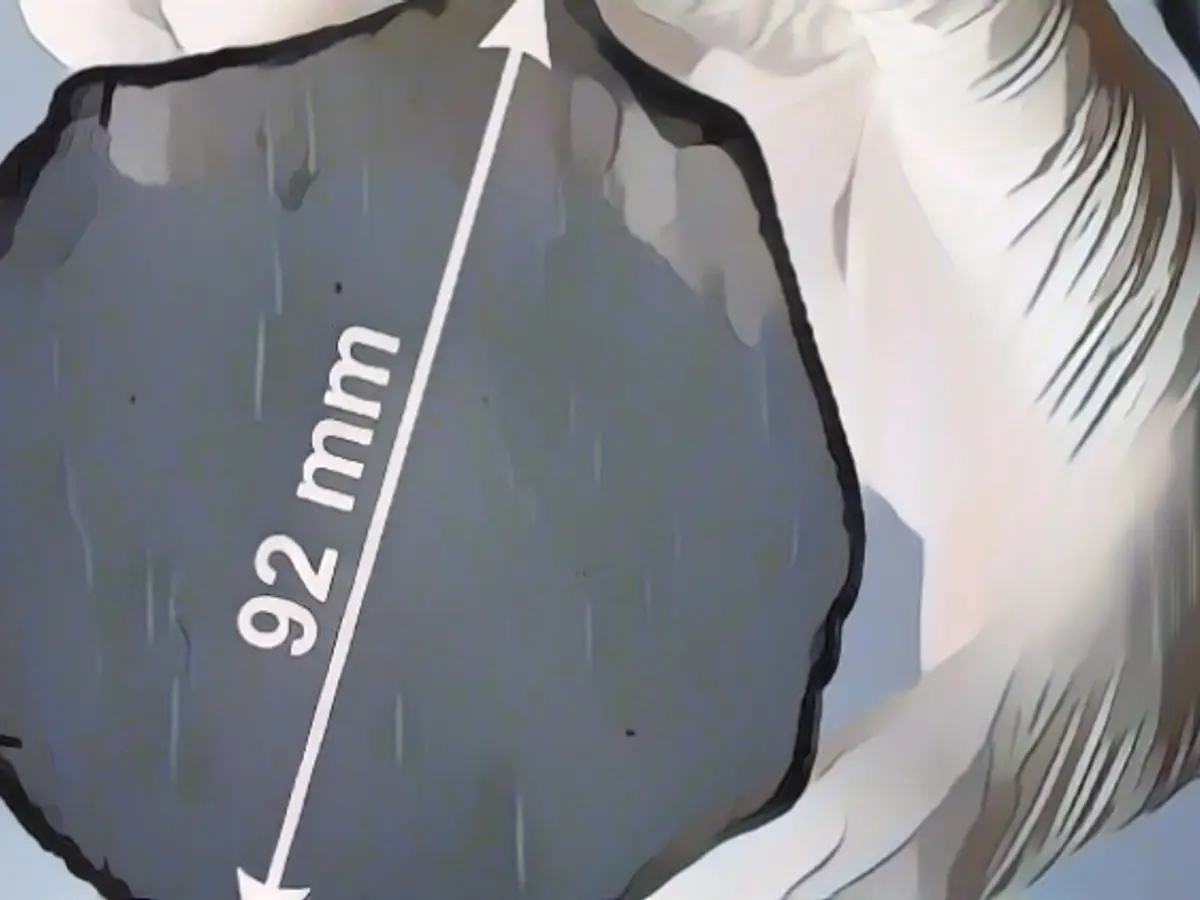

The origins of this cutting-edge technology trace back to the University of Augsburg, where the Bavarian scientists created the "world's largest" synthetic diamond six and a half years ago. The 155-carat gemstone featured an unusual disc shape with a diameter of 92 millimeters, deposited layer by layer onto an iridium base using plasma at several thousand degrees under negative pressure.

The Augsburg scientists realized early on that this material was perfectly suited to high-performance electronics and founded Augsburg Diamond Technology GmbH in 2015 to commercialise their groundbreaking findings.

A Giant Leap in Performance

Diamond Foundry has leveraged this technology to produce diamond wafers of less than three millimeters thick and 100 millimeters in diameter for efficient heat dissipation. As reported by the Wall Street Journal, CEO Martin Roscheisen announced that using this cooling material allowed chips to be operated at twice the otherwise possible clock rate without failures, resulting in a tripled performance for certain Nvidia chips.

Pushing the Boundaries

Diamond Foundry has already produced hundreds of diamond wafers, attracting interest from major chip manufacturers and even defense companies and electric vehicle manufacturers. The team aims to accelerate microchips and electronic devices while minimizing the required space. At current prices, diamond wafers are even cheaper than silicon carbide wafers, used for manufacturing highly efficient power semiconductors.

Roscheisen's company faces competition, with other approaches under development. For example, Intel is working on mounting microchips on a glass base, which could enable the production of mega-chips combining multiple small chips (chiplets) with high power consumption and heat generation.

Exploring Alternatives

Other potential alternatives to silicon in the future could include boron arsenide, which conducts heat less effectively than diamonds but is still a semiconductor. Powerful microchips could be developed from this material in the future.

Lastly, Andy Bechtolsheim, co-founder of Sun Microsystems, envisions a sandwich-like architecture, featuring glass at the top for fast communication, layers of silicon in the middle for processing, and a diamond wafer at the bottom to dissipate heat.

The Power of Synthetic Diamonds

Synthetic diamonds offer excellent thermal conductivity, making them an ideal choice for heat dissipation in high-power computing and artificial intelligence applications. Element Six (E6), part of the De Beers Group, has developed a copper-diamond composite material to improve thermal management in semiconductor devices.

This composite material boasts thermal conductivity in the 800 W/mK range, optimized for high-demand applications like AI, HPC, and GaN RF devices. The copper-diamond composite addresses thermal management challenges, improving performance and reliability while reducing cooling costs for next-generation AI and HPC devices.

Overcoming the Thermal Management Conundrum

This technology offers a substantial improvement in thermal management, unlocking the potential of high-power electronic devices. By using diamond-cooled microchips, developers can expect reduced thermal management bottlenecks, increased device reliability, and improved power output. In the future, smaller, more compact high-performance computing devices might become a reality, thanks to this innovative solution.